Ratchet and Pawl Shaft Connector

Linear Motion Gear Attachment

I designed these parts for the VEX Online Competition as a proposal to VEX Robotics to create these new parts and sell them. The ratchet and pawl connector was my very first project with 3D design. I used Fusion 360 for both projects and learned with experimentation and trying things out in the application.

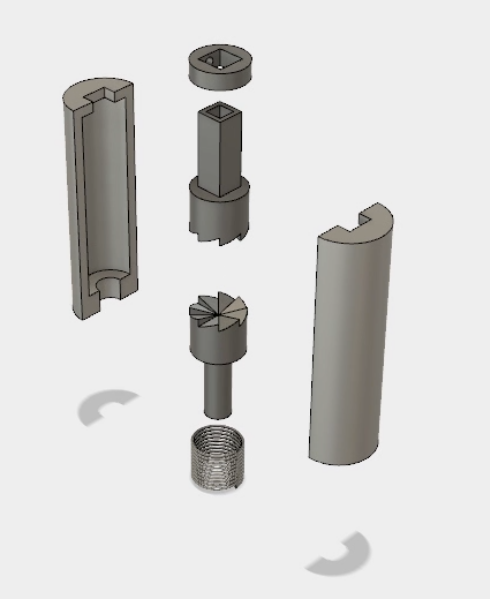

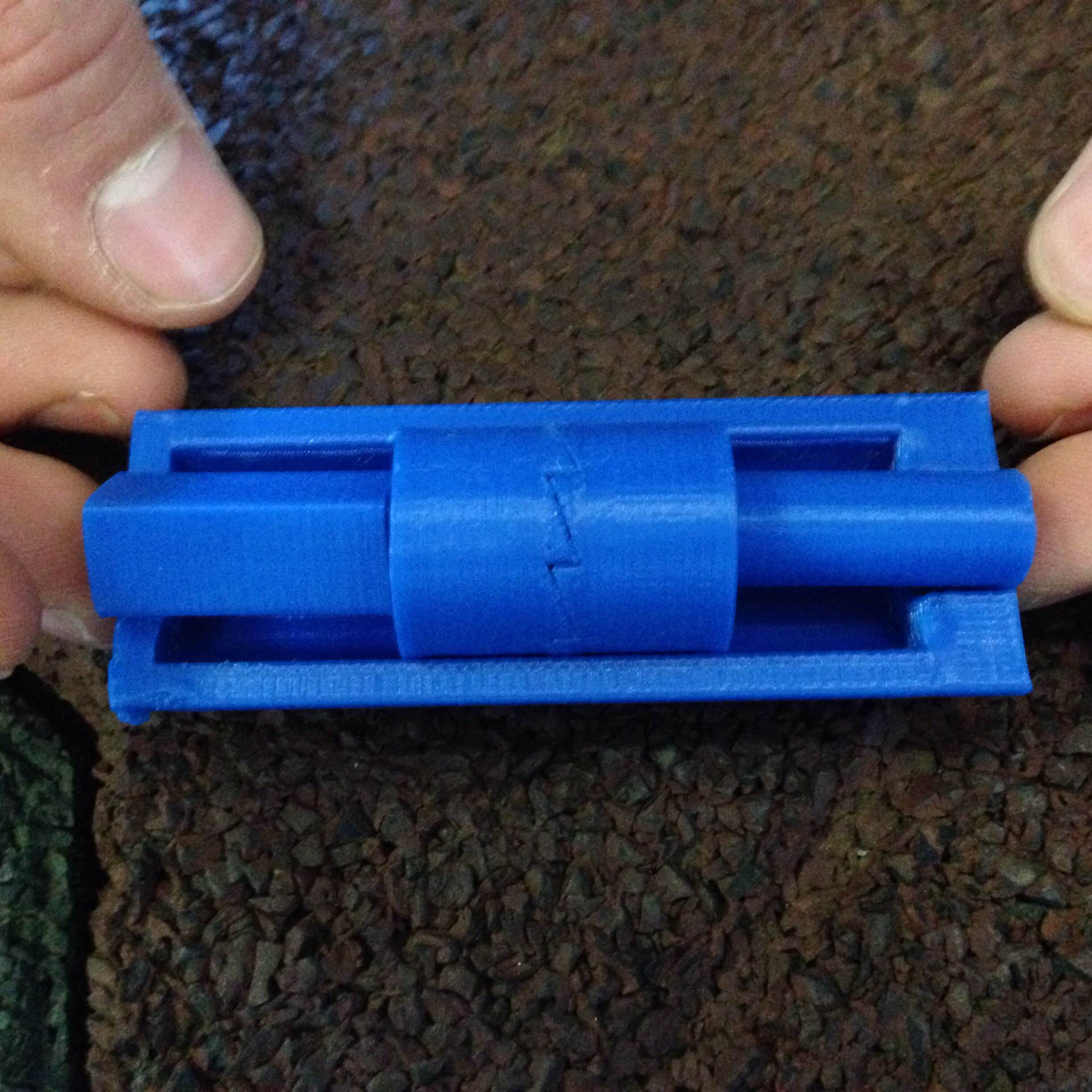

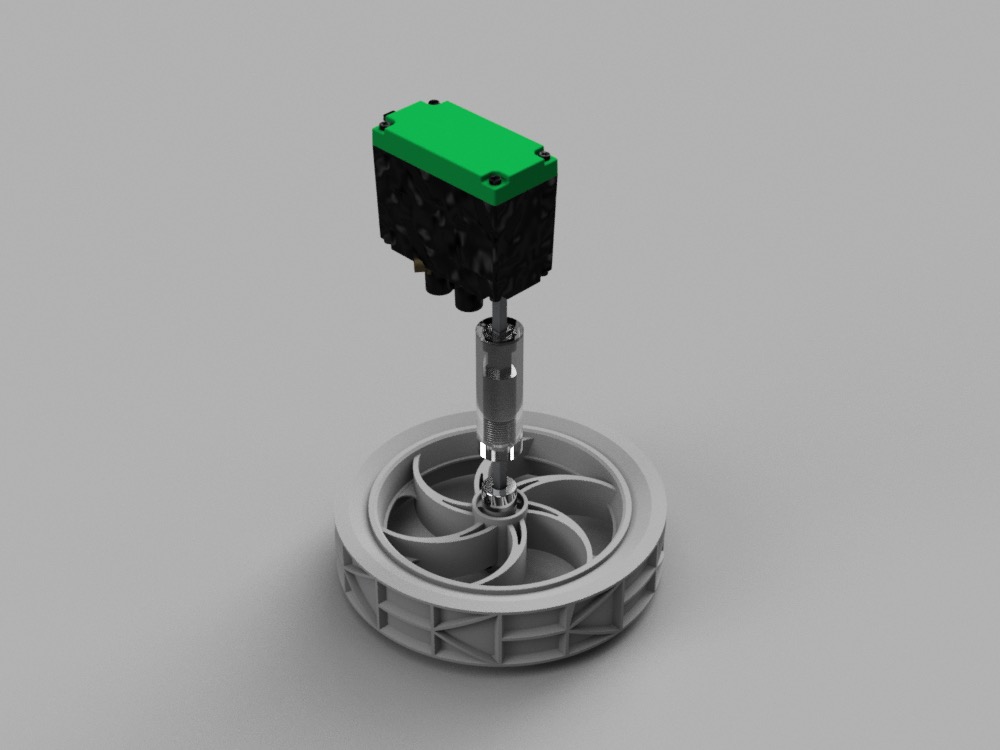

This part works as a ratchet that can connect two shafts together. It allows free rotation in one direction and locked rotation in the other. I printed the part for prototyping. However, since the part would need to be metal to work at the intended scale I could only analytically demonstrate a practical use for it. This was also my first time animating a render of a modeled part.

Animation of Ratchet Pawl Connector Components

Printed Ratchet and Pawl Shaft Connector

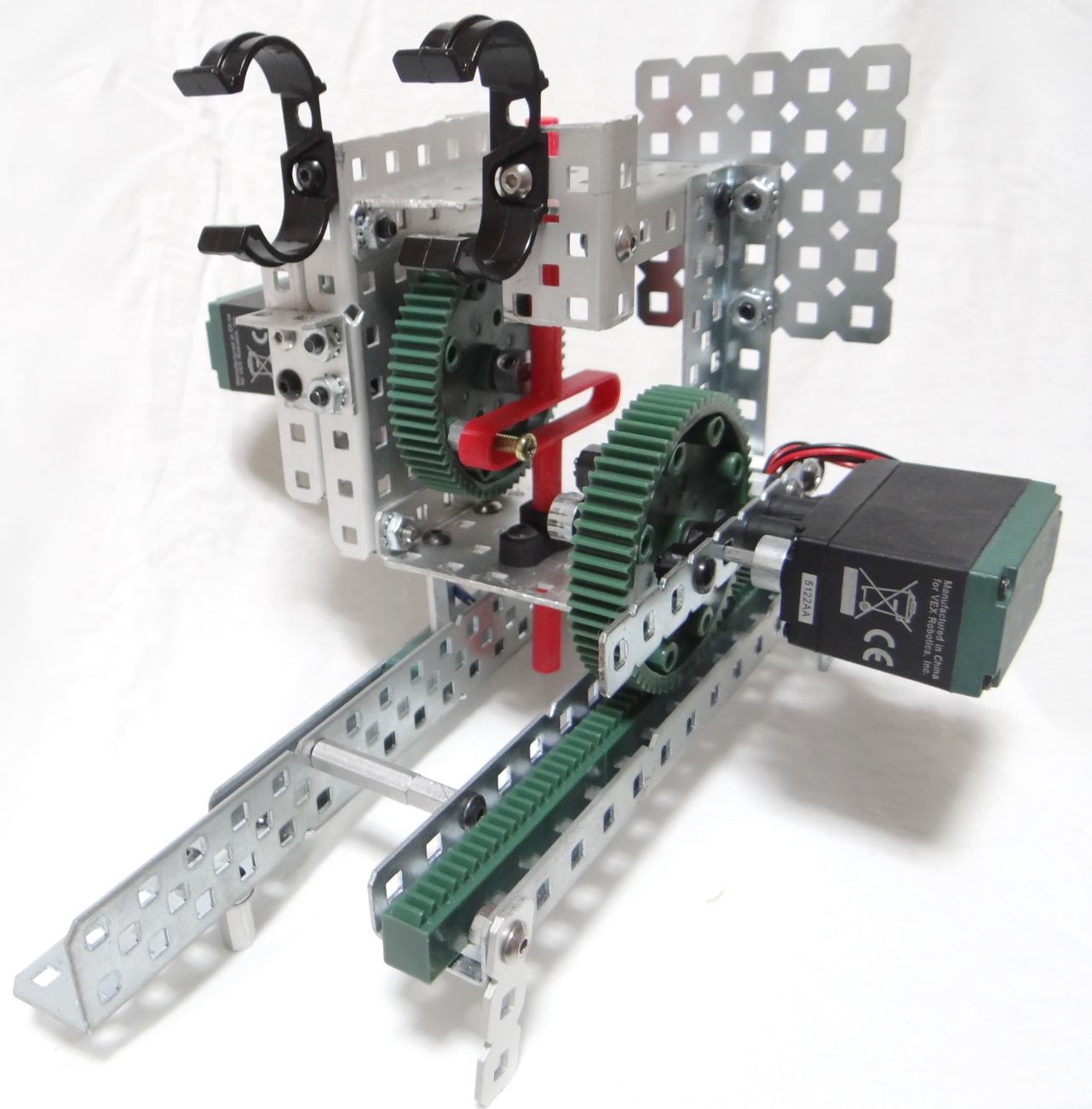

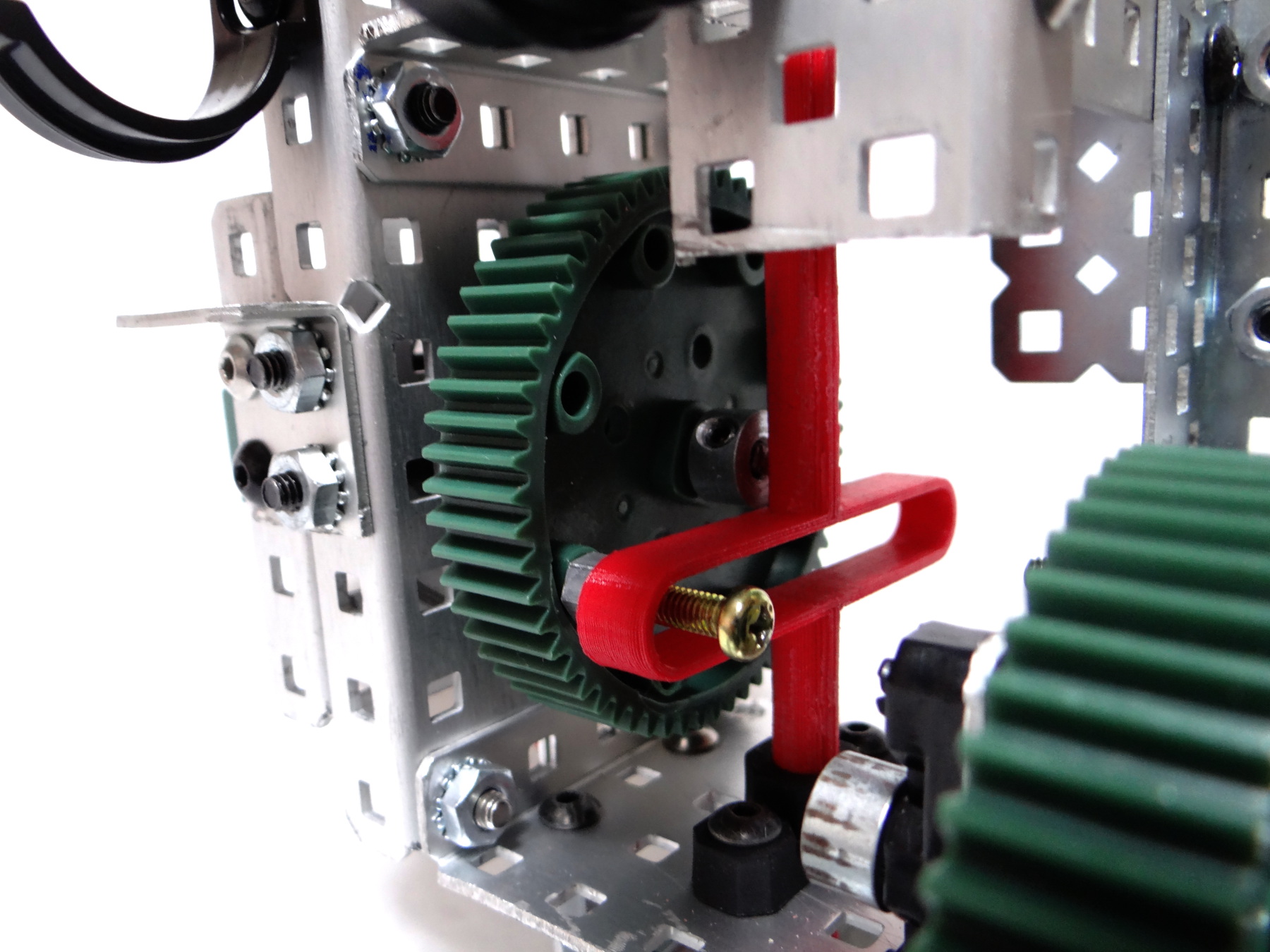

Part with Wheel and Motor Setup

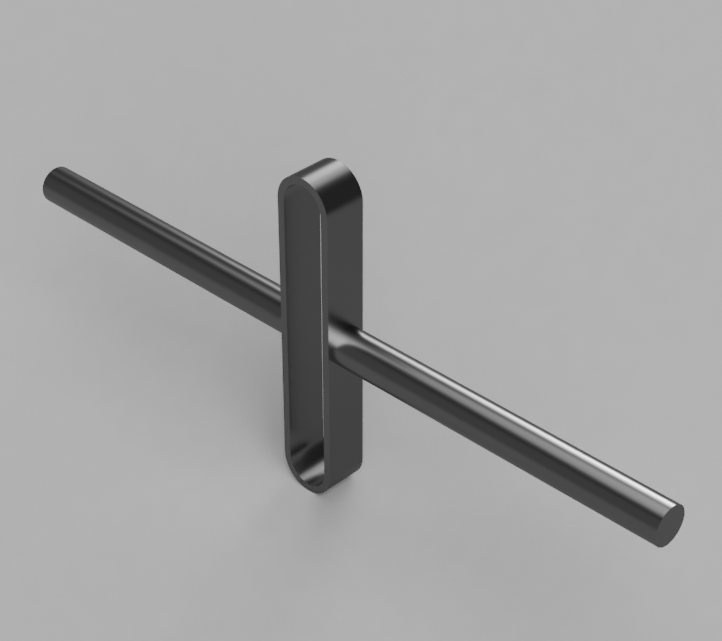

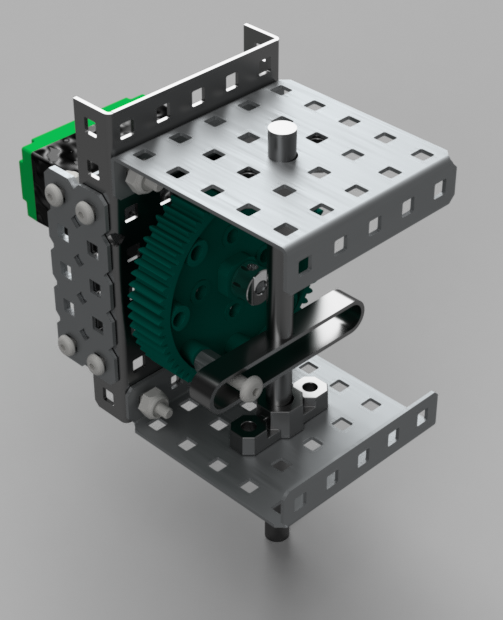

The second part that I created was a finalist in the competition. It was a simple but effective linear motion converter. When attached to a rotating pin it will only move in the y direction.

Animation of Piano Player Robot with Printed Part

To physically test my design I printed it and implemented it into a robot that would slide up and down a rail and “play the piano” by pressing the keys with the linear gear attachment. I demonstrated and presented this for elementary school classes. The design was successful. The entire process taught me about scaling designs to work with defined measurements, and the importance of finding real life applications for them.